Microbial Freeze-dried Powder Lab-Scale Production Service

Backgrounds Services Case Study Brochures Advantages FAQs

Creative Biolabs is an expert in developing live biotherapeutics solutions, offering flexible development services and experiences tailored to each project.

Backgrounds of Freeze-drying

Freeze drying is commonly used to remove water to enhance the storage stability of probiotics. The use of freeze-drying methods and the key parameters of this process are critical in providing high viability levels. In freeze drying, the product is frozen

below the critical temperature of the formulation. The freezing process is then followed by primary drying, in which chamber pressure is reduced, shelf temperature is usually increased, and unbound water is removed by sublimation. Finally, a secondary

drying step is carried out to remove the bound water by desorption, and the product gradually returns to the ambient temperature. In the freeze-drying technique, the important factors including pH of the medium, the content of protective compounds,

prehistory of biomass, initial cell concentration, freezing rate, and temperature should be controlled. Osmotic shock and membrane damage are key and important factors in the loss of activity during freeze-drying, which is caused by intracellular

icing and recrystallization. A variety of protectants have been added to drying media before the processes of freeze drying to protect the viability of probiotics during dehydration.

Probiotic Lyophilized Powder Production Services

Key Protocol

-

Strain Preparation

-

Pre-experiment

Conduct the pre-experiment to explore the strain harvest conditions, lyophilization process, and evaluate the CFU of the strain lyophilized powder product.

-

Formal Experiment

Conduct a formal experiment, and confirm the CFU of the final strain lyophilized powder product.

General Information of the Product

-

CFU/vial: As required (Custom).

-

Format: Lyophilized powder

-

Storage: 4℃ or colder

-

Packaging: Penicillin vial (vacuum) or ampoules.

-

Reconstitution: Add the sterile solution required to achieve the indicated bacterial density.

-

The lyophilized powder is only composed of bacteria and cryoprotectants (placebo).

-

Placebo, a cryoprotectant made of sugar and skim milk, is not toxic to strain or animals (mice).

Simple Steps Researchers Need to Do

-

According to the actual CFU/vial provided by Creative Biolabs and the required bacterial density, calculate the exact amount of the solution required to resuspend the lyophilized powder. (If you tell us the bacterial density in advance, we will calculate

it and display it on the product label).

-

Choose the correct solution to resuspend the lyophilized powder, generally the control for your experiment, e.g. PBS, normal saline solution.

-

Under aseptic conditions, add the sterile solution required to achieve the indicated bacterial density.

-

Allow the vial to reconstitute for several minutes at room temperature with gentle agitation. Avoid vigorous shaking that can cause foaming.

-

Dissolve and mix well, then use bacterial resuspension as soon as possible to avoid affecting the CFU of the product.

-

Do the same for placebo.

Case Study

Case 1: Bacteroides vulgaris Production

Objective

According to the design of the animal experiment, Creative Biolabs produced the Bacteroides vulgaris (CAT#: LBST-025FG) lyophilized powder for the client. The client gavaged the mice the required

CFU of Bacteroides vulgaris daily for a certain period to assess the effect of Bacteroides vulgaris on the disease.

Our Solution

According to the client's animal experiment program, including the CFU required per mouse per day and the number of mice, if conditions permit, Creative Biolabs divided the total CFU required per day into the same vial, which can not only maintain the

consistency of the product but also simplify the experimental steps and improve the efficiency.

Results

-

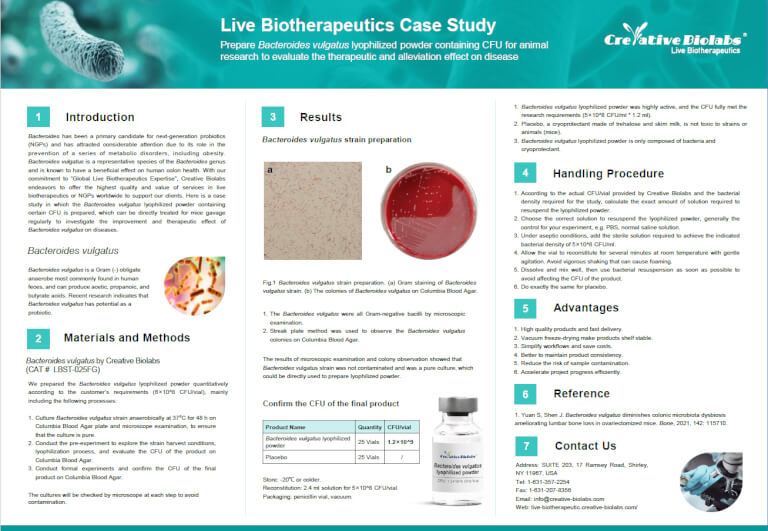

Bacteroides vulgatus strain preparation

Fig.3 Bacteroides vulgatus preparation. (a) Gram staining. (b) The colonies on Columbia Blood Agar.

The results of preparation showed that the Bacteroides vulgatus strain was not contaminated, which could be directly used to prepare lyophilized powder.

-

Confirm the CFU of the final product

|

Product Name

|

Quantity

|

CFU/vial

|

|

Bacteroides vulgatus lyophilized powder

|

28 Vials

|

1.5×10^9

|

|

Placebo

|

28 Vials

|

/

|

Table 1 Specification and quantity of Bacteroides vulgatus and placebo.

Case 2: Ruminococcus bromii Production

Objective

The client was working on a project in which the probiotic Ruminococcus bromii (CAT#: LBSX-0522-GF79) should be used to treat the CRC mouse model.

Our Solution

We provided the client with 1g lyophilized Ruminococcus bromii powder. (Foil bag)

Project Goal

A research team required a custom, high-concentration preparation of Prevotella copri (CAT#LBST-001FG) for oral gavage in mice. The specific application demanded a precise concentration of 5×108 CFU/mouse, with each mouse receiving a 100 µL gavage volume. Furthermore, the client needed a total of 16 vials of the frozen bacterial preparation.

Our Solution

We successfully undertook the custom lab-scale production and preparation of Prevotella copri. Leveraging our expertise in microbial culturing and handling, we:

-

Optimized Culture Conditions

-

Concentration and Formulation

-

Aseptic Processing & Vialing

-

Cryopreservation

Results

We successfully delivered 16 vials of custom-produced, high-titer Prevotella copri in a frozen format, meeting the client's precise specifications for their in vivo mouse gavage studies. This project demonstrates our capability in providing tailored microbial solutions for complex research needs, ensuring the highest standards of quality and reliability.

We provided the client with 1g lyophilized Ruminococcus bromii powder. (Foil bag)

Download Brochures

Advantages

-

High-quality products and fast delivery.

-

Vacuum freeze-drying makes products shelf-stable.

-

Simplify workflows and save costs.

-

Better to maintain product consistency.

-

Reduce the risk of sample contamination.

-

Accelerate project progress efficiently.

Creative Biolabs' more than 10 years of CRO service experience provides you with the confidence to find the right partner. Services tailored to your needs provide an extension to your lab and accelerate your research projects. If

you need small-scale customized production services, please do not hesitate to contact us, we can fully provide customized solutions according to your project research.

Frequently Asked Questions

Q. What is the packaging of microbial lyophilized powder?

A. You can choose any of the following to package the product.

1. Glass ampoules

The microbial cultures are freeze-dried in glass ampoules and sealed with flame under a vacuum. This format is suitable for long-term preservation cultures, making it easier for researchers to use the same batch of strains and reducing genetic variation.

2. Capped vials

Another format is to freeze-dry the cultures in small penicillin bottles with a crimped foil that holds the rubber seal in place. This is easier to open than a glass ampoule, however, in such vials, the shelf life of the culture is shorter and is suitable

for the storage of microorganisms used for a short period. Such as animal gavage experiments and other related microbial research.

Q. What affects the stability of the product?

A. The method of storage and the packaging material and methodology will influence the shelf life of the dried product. Common reactive agents to decrease the shelf life of products include; oxygen, moisture, light, microbial contamination, and elevated

temperatures. Therefore, the packaging material will be a different type of barrier for these reactants. Generally, freeze-dried products are stored in ampoules or glass bottles. For dry products, there are other options such as high-barrier

plastic bags and blister packaging.

Q. What are the applications of freeze-drying technology?

A. Lyophilization is a common process employed to preserve bacteria, either during concentrated culture production in the food and pharmaceutical industries or for culture collections. With in-depth research on the treatment of diseases with probiotics,

the development of biomaterial-based encapsulated probiotics can significantly improve their viability and efficiently treat specific diseases or repair tissue. Freeze drying has been the classic method of producing dried bacterial powder.

There are many industrial applications for equally preserved microorganisms. Microbiological quality control is necessary for the pharmaceutical, food, and beverage industries. The freeze-drying technology has been used in the preservation

of bacterial strains for several applications, mainly in the production of probiotics for the treatment of gastrointestinal disorders.

For Research Use Only. Not intended for use in

food manufacturing or medical procedures (diagnostics or therapeutics). Do Not Use in Humans.

Related Services